Service Items

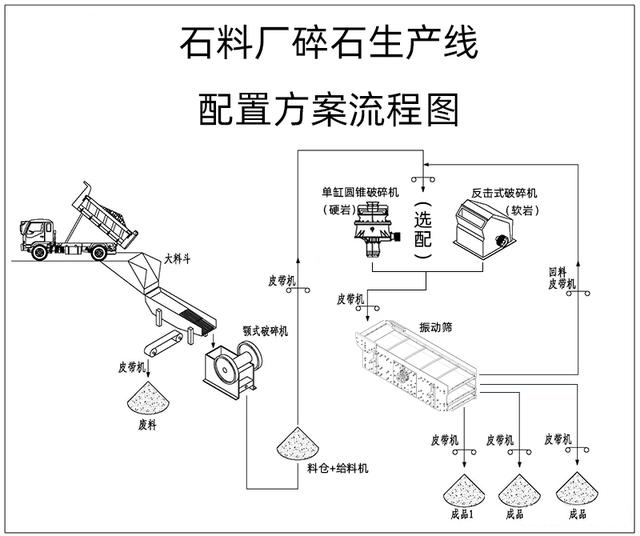

The stone and sand processing process in the stone factory can be briefly described as: feeding stage - coarse crushing stage - medium and fine crushing stage - screening stage - sand making stage - screening stage - sand washing stage (optional) ; A complete set of stone plant equipment corresponds to the process, including crushing equipment: jaw crusher, cone crusher, impact crusher; auxiliary equipment: vibrating feeder, circular vibrating screen, and belt conveyor.

How to design the stone crushing production line plan? Free customization! Based on the materials, production scale, discharging requirements, investment budget, etc., the technical staff recommends two stone crushing production line design plans for stone factories. 1. Discharging: 12, 13, 24 stones (standard version of the stone production line) Vibrating feeder + jaw crusher + single cylinder cone crusher/impact crusher + vibrating screen + belt conveyor 12, 13, 24 stones (standard version of the stone production line)

Process flow: Standard two-stage crushing process, multiple crushing and screening, better stone particle size. Single-cylinder cone crusher and impact crusher are both secondary crushing equipment. Single-cylinder cone crusher is more suitable for processing high-hard materials such as granite, basalt, quartz stone, and impact crusher. It is more suitable for processing limestone, coal gangue, construction waste and other medium and low hardness materials. Production line advantages:

01. Stage-by-stage crushing can control each process more strictly and accurately. The operation precision is higher, the material is produced more strictly, and higher-quality stone materials can be processed;

02. There are many models of equipment available for each production link, which can be upgraded to a combination of different production lines by adding or removing equipment configurations. For example, a sand making machine can be introduced into the crushing production line to form a sand making production line;

03. The production capacity range is large, and the cooperation of multiple units can achieve a production line with a daily output of 10,000 tons. Combined with the transfer silo, it can be configured into a large or ultra-large stone crushing production line. Anhui customer tuff stone production line case for your reference selection.

Production capacity: 1200t/h Finished product specifications: 0-5mm, 5-12mm, 12-25mm, 25-31.5mm Configuration equipment: MGD1360 vibrating feeder; MC300Z single-cylinder hydraulic cone crusher; MC500X single-cylinder hydraulic cone crusher; 3MA3082 circular vibrating screen; 2MA3082 circular vibrating screen; MGB1422 silo feeder; 00:30 Solution advantages: It is equipped with powerful crushing equipment (MJ jaw crusher + MC single-cylinder cone crusher) to produce high-quality tuff stones. It is a fully enclosed environmentally friendly factory, and a bag dust collector and other environmentally friendly facilities are installed inside the factory to prevent dust from spilling and dust removal. Reduce noise and create a green and environmentally friendly production workshop.

24-hour sales hotline:+8613897984610

International Trade Hotline:+8613897984310

E-mail:luyepeng@msrmining.com

Adress:Kafa 2nd Road, Tiexi District, Shenyang City

©2021MSR Copyright